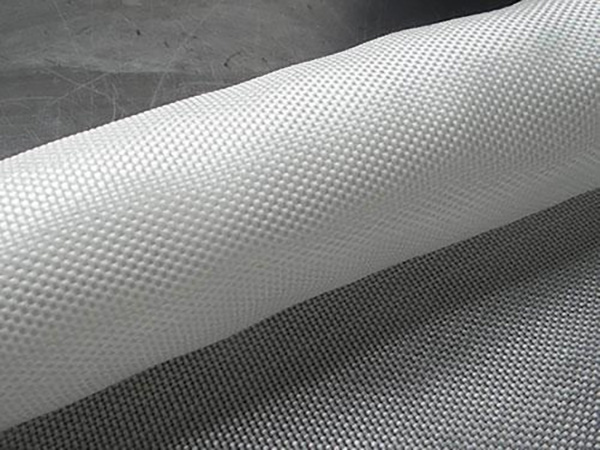

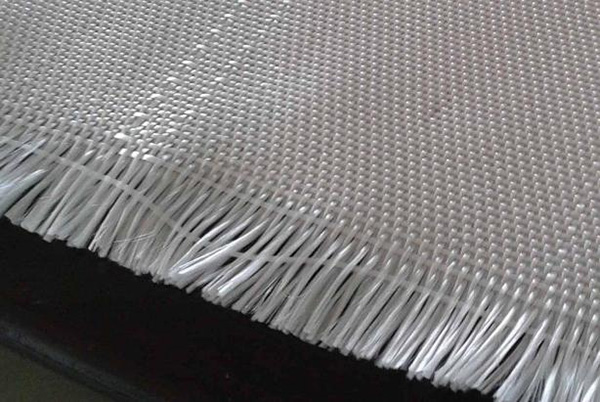

Reinforced high strength spun polyester filament woven geotextile

Short Description:

Filament woven geotextile is a kind of high strength geomaterial made from synthetic materials such as polyester or polypropylene after processing. It has excellent physical properties such as tensile resistance, tear resistance and puncture resistance, and can be used in land regulation, seepage prevention, corrosion prevention and other fields.

Products Description

Filament woven geotextile is a classification of geotextile, it is high strength industrial synthetic fiber as raw materials, by weaving process production, is a kind of textile mainly used in civil engineering. In recent years, with the acceleration of infrastructure construction around the country, the demand for filament woven geotextiles is also increasing, and has great market demand potential. Especially in some large-scale river management and transformation, water conservancy construction, highway and bridge, railway construction, airport wharf and other engineering fields, has a wide range of applications.

Specification

Nominal breaking strength in MD (kN/m): 35, 50, 65,8 0, 100, 120, 140, 160, 180, 200, 250, width within 6m.

Property

1. High strength, low deformation.

2. Durability: steady property, not easy to resolved, air slaked and can keep the original property long term.

3. Anti-erosion: anti-acid, anti-alkali, resists insects and mould.

4. Permeability: could control the sieve size to retain certain permeability.

Application

It is widely used in river, coast, harbor, highway, railway, wharf, tunnel, bridge and other geotechnical engineering. It could meet all kinds of geotechnical projects needs such as filtration,separation,reinforcement, protection and so on.

Product Specifications

Filament woven geotextile specifiation( standard GB/T 17640-2008)

| NO. | Item | Value | ||||||||||

| nominal strength KN/m | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | |

| 1 | breaking strength in MDKN/m 2 | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 |

| 2 | breaking strength in CD KN/m 2 | 0.7 times of breaking strength in MD | ||||||||||

| 3 | nominal elontation % ≤ | 35 in MD, 30 in MD | ||||||||||

| 4 | tear strength inMD and CD KN≥ | 0.4 | 0.7 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | 1.9 | 2.1 | 2.3 | 2.7 |

| 5 | CBR mullen burst strength KN≥ | 2.0 | 4.0 | 6.0 | 8.0 | 10.5 | 13.0 | 15.5 | 18.0 | 20.5 | 23.0 | 28.0 |

| 6 | Vertical permeability cm/s | Kx(10-²~10s)其中:K=1.0~9.9 | ||||||||||

| 7 | sieve size O90(O95) mm | 0.05~0.50 | ||||||||||

| 8 | width variation % | -1.0 | ||||||||||

| 9 | woven bag thickness variation under irrigate % | ±8 | ||||||||||

| 10 | woven bag variation in length and width % | ±2 | ||||||||||

| 11 | sewing strength KN/m | half of nominal strength | ||||||||||

| 12 | unit weight variation% | -5 | ||||||||||